Scania R730 - MPG 450

MPG / JH Kran displayed this impressive MPG 450 model on the world's 1st 8-axled Scania for Upplandskranar AB in Sweden.

Early in the morning they where preparing the crane and it was folded down, which shows the real size of this machine beside the cab.

The main crane is 9x extending and reaches up to 33,25 meters with a stunning 6,5 tons capacity. Maximum capacity is 132 tons at 3 meter and for example at 11,6 meter it is 29,6 tons, impressive values!

The 6x extending jib ads 22,5 meter to the outreach, coming to a total of 55,78 meters hydraulically. On that distance it can still lift 620 kg. The tipping height of the jib is close to 38 meters and the jib can lift a load of up to 10,14 ton there. Maximum outreach with manual extensions is 65,7 meter with 310 kg.

The previous versions of this crane where installed on 7-axled Scania's, like on the last Bauma. This time JH Kran added 1 more axle to this Scania R730 to get better axle loads, for example less than 7,5 tons per axle when the ballast & jib are off. This is important for usage in Stockholm where the old town has limits to axle weights.

The base for this truck is a Scania R730 8x4. They added 2 steering axles in front and behind the tandem making it a 16x4*12 The additional steering is provided by dual VSE steering units. Total weight with everything on board is 78 tons, with part ballast like here it's 68 tons and 62 tons without any ballast. If you also leave the jib off, you get a weight around 57 tons. So many different axle weight combinations are possible, depending on the situation.

The Scania R730 was equiped with the side-flaps behind the cab that are normally used on heavy haulage tractors. The overall length of this truck is 14,3 meters.

Ballast ist mounted behind the crane for full stability, maximum 16 tons.

A cabin has been installed at the crane, a new feature on MPG cranes.

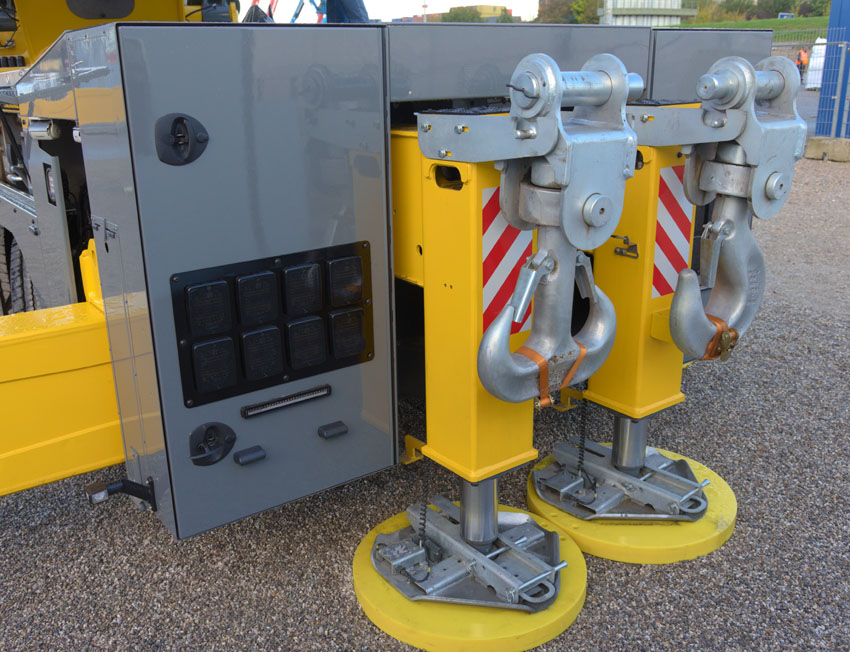

At the rear we see these big outriggers, as the crane is rear mounted and high forces will work on them. They also hold the heavy hooks of the crane.

This is the reason for the side-flaps behind the cab. The exhaust had to be moved, as all the space on the frame is used by axles. Below the exhaust they installed a large electrical motor with pumps, so that the crane can run on electrical power from 400V/63A sockets. At the left side we see the cable roll for the power.

During the day they set up the crane with 4 + 2 extensions, rougly 30 meters of height.

A very interesting and impressive crane unit!

Here is a video of this truck.

And another video of Frank Steckemetz during tests of the steering, befor a crane was installed.