At the end of december 2003 the company Ter Horst of Terborg (NL) had to install a 20 ton machine at De Goudsche Machinefabriek in Waddinxveen.

Therefore they used their brandnew Volvo FH12-500 10x4 with a Effer 950.

|

|

This is how the truck came to the company at this (dark) wintermorning. Loaded with a Forktruck, steel plates and a pallet with wood. At the back we see the large Effer 950 crane. |

|

At first the forktruck is unloaded with the crane. It has to fill up a gutter with wood an steel plates so that the lowloader can drive over it. The gutter is there for the rail of the gantry crane in the back. |

|

The forktruck and the plates are unloaden. At the front of the floor we see a cross-beam for lifting. The entire truck has been finished nicely with a complete side-cover and toolboxes. Even behind the crane they mounted a toolbox. |

|

The truck is a Volvo FH12-500 10x4 with a Globetrotter XL cab. The base is formed by a 8x4 truck that became a extra steerable 10 ton axle at Estepe. |

|

The crane is an Effer 950 4S, it has a maximum load capacity of about 81 t/m. The crane can be extended 4x and than has a length of 12 meter at which it still lifts 6,55 ton. The weight of such is crane is about 8 tonnes. This causes the truck to lean back somewhat when it is not loaden. In the front board the front support legs are mounted. The crane and the loadfloor have been mounted at Buitendijk from Emmeloord. |

|

This Scania with trailer transports the rest of the machine. That is about 22 tonnes of seperate pieces. |

|

The machine was brought by the company Versteeg who did this with a twinsteer Renault Premium and a 2-axled Nooteboom lowloader. The machine was pushed backwards into a sidedoor of the building. Here we also see the gutter that had to be filled with wood. |

|

The entrance of the buidling wasn’t much wider than the lowloader itself, making this a not so easy job. |

|

Here we see how narrow the door actualy is. |

|

After several try’s the lowloader managed to get in. |

|

The Volvo is driven inside via another door. |

|

Here he had to drive in between other machines, on a also not so wide track. |

|

The truck is driving backwards until it stands beside the lowloader. |

|

If the truck is positioned as near as possible to the lowloader, the support legs are lowered and the crane is activated. |

|

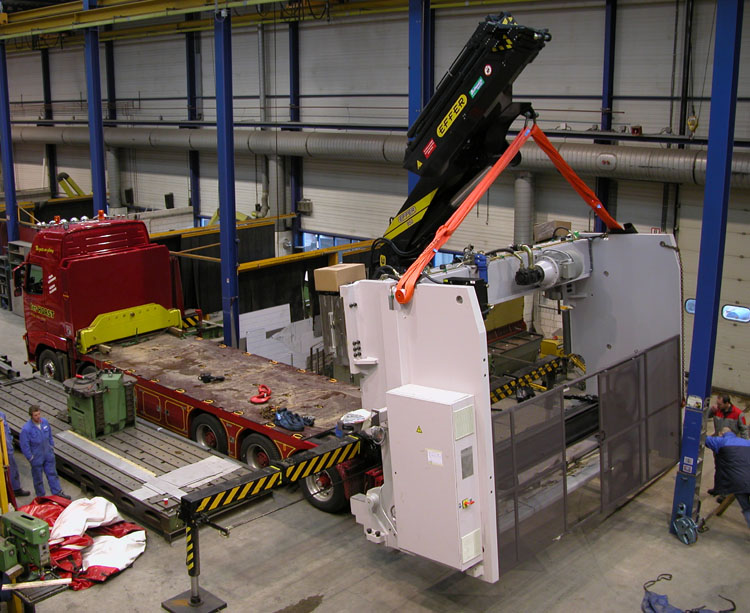

The 20 ton machine is lifted of the lowloader with ropes. The machine isn’t hanging at the top of the crane but at a special heavy duty hook that is mounted nearer to the center of the crane. Here it also is getting clear why this crane is mounted at the back of the truck. At this point the truck is namely the ballast for the crane. Otherwise such loads could never be lifted behind (and not over) the support legs. |

|

After the lowloader has driven away they can put the machine on the floor. |

|

Here we see how near-by the machine hangs to the crane. This kind of loads can only be lifted this close to the center of the crane. This Effer can lift up to 31,5 tonnes on his heavy duty hook.

The machine is now lifted at one side so that rollers can be mounted underneath it at this side. |

|

Now the machine is being lifted at the other side. By using these rollers, the crane only has to lift (about) half of the total weight of the machine. |

|

By rolling at this side and lifting/pulling at the other side the machine is rolled towards it’s position. On the crane we see a stick with lights in it. At this moment the red one lights. This means that the crane, in this postition, has reached it’s maximum lifting capacity. Extending any further isn’t possible. |

|

That is why the rollers are now being placed underneath the other side of the machine. |

|

Then the machine is lifted and rolled further towards it’s position. |

|

After doing this a few times, and also moving the truck twice, the machine is getting near to the position where it has to be. Here the orange one lights, which means that the crane is near it’s maximum capacity. |

|

At a certain point the machine was to far away for the Effer. That is why they used a overhead crane. Unfortunately this one didn’t manage to get al the way into the back of the building. That was because two lighter cranes where hanging in front of it. |

|

|

This made them decide to use two of these overhead cranes together with the cross-beam, to lift the machine at one end. The other end was lifted with the Effer. This way they could put the machine onto it’s final position. |

|

The Volvo is being driven away, the next day it would be busy with installing the rest of the machine. |

| |

My thanks at this point go out to Arie van Urk for inviting me.

His photoreport can be seen at this website: Schwerlastinfo

|

| |

| Back to the: Events index / Volvo index / Effer index |