At 11th of june there was an open day at the company Moog from Deggenhausertal

In this report the vehicles that where displayed there will be presented. |

|

At the middle of the yard stood this MAN 6x2 which is equiped with a bridge inspection unit of the type MBL 1600 T. |

|

This is a unit with a worksman basker. The extra axles under the MAN are not necessary because of the total weight, but are there for stability. They don’t have suspension, they are bolted directly to the chassis. The truck is in working position here, meaning the suspension is on it’s lowest and the extra axles are therefore on the street. Because these machines can drive while they work they can’t have outriggers. The extra axles provide the needed stability. Traction comes from a steel wheel that is pushed on the tyres of the driven axle (behind the rubber part). This wheel is driven hydraulically. |

|

Here the arm is in working position. It can move up- and downwards (below the bridge). All 3 boom parts can telescope, the part with the basket even twice. |

|

A bigger unit, equiped with a platform instead of a basket, is this one that has been built onto a trailer. It is a 3-axled trailer with 2 extra axles for stability. The first one of those is tilted 90 degrees to get more ground clearance at the front of the trailer. |

|

This unit has a platform that is tilted underneath the bridge. This will be demonstrated later on. The 2 driving wheels, above the second last tyre, can be seen clearly here. |

|

A smaller unit with a platform is mounted onto this 4x2 Scania. The 2nd axle is the extra one for stability. The driving wheel is also visible here. |

|

Beside all the built up machines, there was also this Scania 4x4 tractor standing around. |

|

Not less interesting was this Mercedes Actros that was built up in the garage. It is a 4x4 that also has steering on both axles. It is getting a unit for rail-usage. |

|

Also for rail-usage is this Scania R114G-340 8x4 with a basket-unit. |

|

This vehicle doesn’t has any extra axles (no use on the tracks), therefore it uses 4 outriggers. The wheels with which it drives on the tracks are mounted behind the cab and at the end of the chassis. At the rear there is a cabin, probably for when the vehicle is driving in the other direction (at the tracks). |

|

|

Another vehicle for use on the tracks is this Mercedes 2631 6x4 of Wemo with basket-unit. |

|

A remarkable feature about this truck is, that the entire unit can be demounted ... |

|

... to exchange it for this unit which can operate with 3 baskets at the same time. |

|

Another unit with a platform, this time mounted on a Mercedes Actros 2531 6x2. This one also has 2 extra axles for stability, the axles 2 and 5. |

|

|

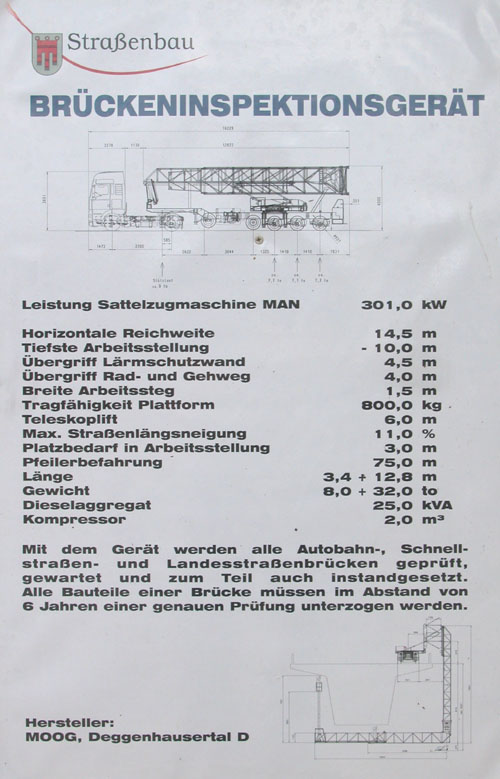

This is the technical specification of one of Moog’s largest bridge inspection units. This machine is being used in the Vorarlberg-region in Austria for inspection of a lot of there bridges. |

|

It is being pulled by this MAN TGA 18.410. During operation, this tractor is not attached to the trailer. The trailer has it’s own driving system with an engine and hydraulics. |

|

Here the unit is in it’s working position. The platform has been lowered and is underneath the bridge. As the others, this trailer works without the use of outriggers. Stability comes from 2 extra axles and the normal axles (after the suspension has been lowered to it’s limit). |

|

Here they demonstrate how this units folds together. First thing to do is retracting the platform and turn it away from the bridge. After that the tower is raised and the platform is being tilted upwards. |

|

This unit can work much lower than demonstrated here, as can be seen by the length of the tower. Here the platform is almost ready with tilting. |

|

After that the tower is being tilted upwards. The tower is mounted to a frame that again is mounted onto a turntable. The frame can telescope sideways so that the tower moves over bicycle-roads, pavements and sound walls. |

|

After the tower has tilted, it is rotated 90 degrees. |

|

This way the tower can be layed down on the trailer. This is done with 4 hydraulic cylinders that lift the turntable. |

|

This is how it looks like in transport-position. |

|

And from the other side. At the front they mounted a small Hiab crane. |

| |

| Back to the events index |